锁紧盘在工业变速箱中的应用

锁紧盘在工业变速箱中的应用

Application of Shrink Discs in Industrial Gearboxes

锁紧盘是一种外部锁紧装置,它既有过盈配合的高传递能力,又有传统联结方法的所有优点, 但是其装配和拆卸却更加容易和迅速。当扭矩通过一个轴和一个空心轴之间的联结传递时,当前的解决方案是使用锁紧盘而不是容易发生故障的键联结。锁紧盘的内径通常为14 mm至500 mm。

在本文中,我们将简要介绍RINGFEDER POWER TRANSMISSION的另一个应用解决方案,它是与巴西的变速箱行业客户的设计团队合作开发的。

Shrink discs are external locking devices that provide a high capacity interference fit as well as all positive features of a conventional connection method, but which are much easier and faster to assemble and dismount. When a torque is transmitted through the connection of a shaft and a hollow shaft, the contemporary solution is to use a shrink disc instead of a failure-prone keyed connection. Shrink discs are typically available with inner diameters from 14 mm up to 500 mm.

In this article we take a brief look at another application solution of RINGFEDER POWER TRANSMISSION, which was developed in partnership with the design team of a customer in the gearbox industry located in Brazil.

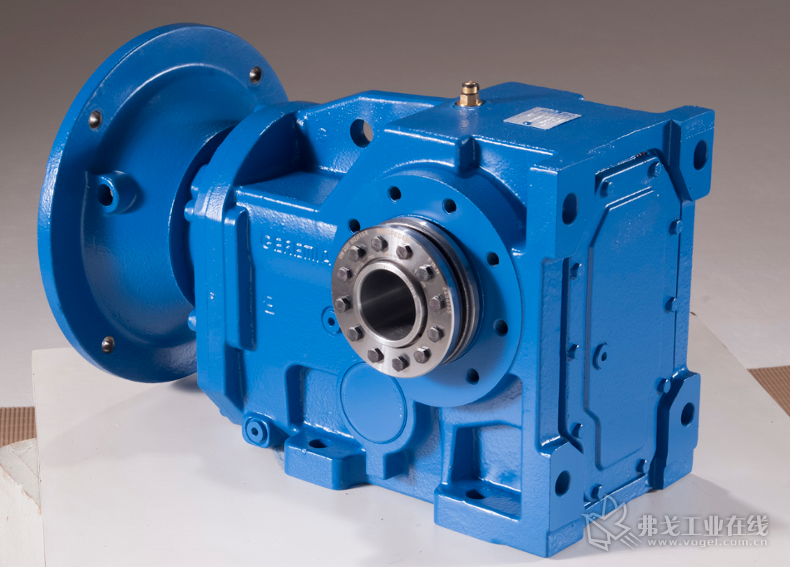

Geremia Redutores / Gearbox with RINGFEDER Shrink Disc 62 RfN 4061

挑战

客户联系RINGFEDER,提出了一个紧急请求,要求为工业变速箱提供解决方案。该变速箱不仅需要满足高扭矩要求,而且必须设计一个直径900mm的空心轴。对于900mm的轴直径,与之相应的锁紧盘当然必须大于标准的制造直径,因此对生产来说是一个额外的挑战。

工作原理

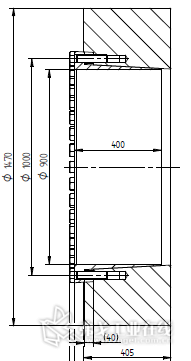

如下图(截面图RfN 4181 900x1470)所示,夹紧螺钉一拧紧,前止推环和后止推环就被沿着锥度方向拉到一起。这会导致空心轴收缩并在实心轴上产生表面压力,从而通过轴与空心轴之间的摩擦确保安全的扭矩传递。

The Challenge

The customer contacted RINGFEDER with an urgent request to provide a solution for an industrial gearbox which not only had to fulfill high torque requirements, but also had to be designed for a hollow shaft with a diameter of 900 mm. For a shaft diameter of 900 mm, the corresponding shrink disc, of course, had to be larger than the standard diameters manufactured and was thus an additional challenge for production.

Functional Principle

As seen in drawing 1 (Sectional drawing RfN 4181 900x1470 to the right), the front and rear thrust rings are pulled together over the taper as soon as the clamping screws are tightened. This causes the hollow shaft to shrink and generates a surface pressure on the solid shaft – thus ensuring a safe torque transmission through friction between the shaft and hollow shaft.

解决方案和制造生产

针对上述特殊要求,原材料性能是保证锁紧盘安全性能的重要参数之一。客户和竞争对手通常不考虑这一点。机床是根据要求和工作所需的理想机器而精确地选择的,它对生产的成本效益有很大的影响,对有竞争力的定价也有很大的影响。

Solution and Production

In regards to the special requirements mentioned above, the raw material properties are one of the most important parameters to guarantee a safe shrink disc performance. This is often not considered by customers and competitors. Machining tools, precisely chosen based on the requirements and the selection of the ideally suited machine for the job, have great influence on cost-efficient production and last but not least, on competitive pricing.

RINGFEDER Shrink Disc 900 RfN 4181 in production

对于我们的客户来说,最可靠、最经济的解决方案是特殊设计的锁紧盘系列RfN 4181。另一个挑战是生产时间,因为急需锁紧盘。我们成功地把标准制造时间缩短到10周。

The most reliable and cost efficient solution for our customer was a special design of the shrink disc series RfN 4181. Another challenge was the production time frame because the shrink disc was urgently needed. We managed it to reduce the standard manufacturing time to only ten weeks.

RINGFEDER Shrink Disc 900 RfN 4181

我们的目标是成为应用导向的解决方案提供商。在这种情况下,我们也成功地解决了客户的应用问题,提供了一个标准产品的特殊版本,即更大尺寸的重型锁紧盘系列RfN 4181。目前,这是巴西最大的锁紧盘。

Our claim is to be a provider of application-oriented solutions. In this case, too, we successfully solved a customer's application problem by offering a special version of a standard product, i.e. a larger size of our heavy-duty shrink disc series RfN 4181. And presently, this is the biggest shrink disc installed in Brazil.

获取更多评论